Enhancing Bespoke Suits Online With Support From 3D Technology

In an era where sustainability is paramount, the tailoring industry has begun to embrace cutting-edge 3D technology to enhance efficiency, reduce waste, and improve customer satisfaction. Whether individuals are searching for bespoke suits online or shopping for inexpensive tailored suits, advancements in 3D scanning and modeling are revolutionizing how garments are designed and produced. This article explores how 3D technology not only cuts down on material waste but also ensures precise fits and optimizes production efficiency while supporting sustainability in fashion.

1. The Role of 3D Scanning in Reducing Material Waste

One of the leading contributors to environmental degradation in the fashion industry is the significant material waste generated during garment production. Traditional tailoring methods often involve a considerable amount of trial and error, which can lead to excess fabric and discarded samples. However, with the advent of 3D scanning technology, the landscape of tailoring is changing, providing an innovative approach that aligns with sustainability goals with bespoke suits online.

1.1 Accurate Measurements and Fit

3D scanning allows for the precise capture of body measurements and movement, enabling tailors to create accurate digital avatars of clients. These avatars ensure that every suit, whether it’s a premium suit or an inexpensive tailored suit, is designed specifically to the individual’s unique dimensions. This level of accuracy is a game-changer. It greatly minimizes the likelihood of producing ill-fitting garments, resulting in less fabric waste from cuts that are not conducive to the final product.

Virtual Fitting Experiences

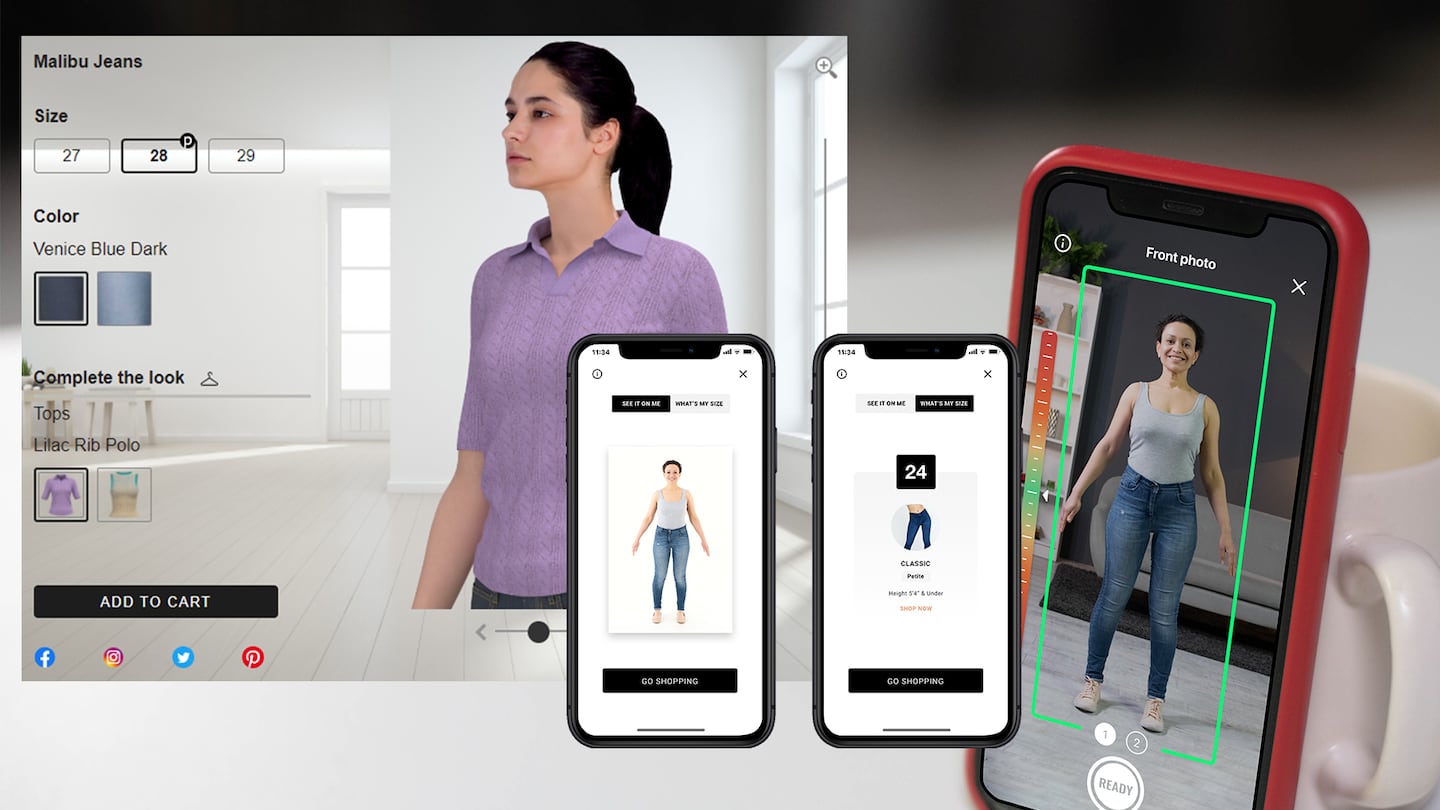

The introduction of virtual fitting rooms powered by 3D scanning technology has transformed how individuals shop for tailored suits. Customers can now try on suits virtually, which significantly reduces the need for multiple physical samples and fittings. This virtual fitting experience not only caters to convenience but also reinforces sustainability by cutting down on the carbon footprint associated with travel and multiple fittings.

This method is particularly advantageous for brands offering bespoke suits online, as it allows clients to see how different fabric choices and designs would fit their digital avatars. With this insight, customers can make informed decisions, resulting in a higher satisfaction rate with their final purchase.

1.2 Streamlined Production Processes

In addition to reducing material waste, 3D technology enhances the overall efficiency of the production process. Traditional tailoring often requires physical fittings, which can be time-consuming and resource-intensive. With 3D scanning technology, suppliers can analyze the digital data and produce garments without multiple fittings, significantly speeding up production times. This efficiency allows tailors to allocate resources more effectively, reducing both time and costs associated with labor and materials.

For example, bespoke tailors initially relied heavily on fabric samples and physical fittings to assess how materials would drape and fit. Now, with 3D modeling, they can create simulations that showcase how design choices will translate into finished garments. This not only improves the design process but also leads to more sustainable practices by minimizing the need for excess materials during the sample-making process.

1.3 Reduced Sampling Production

Another significant benefit of 3D technology in tailoring is the ability to significantly reduce sampling production. With traditional methods, creating a sample garment to test fit and design often required substantial amounts of fabric and labor. 3D technology allows tailors to visualize and simulate designs digitally, reducing the need for physical samples.

This approach is advantageous when designing premium suits. Instead of creating multiple prototypes, tailors can adjust the digital model with simple clicks, modifying design elements like shoulder width, sleeve length, and overall fit instantly. This iterative process saves both time and resources while ensuring that the final product is as close to perfection as possible.

2. Optimizing Production Efficiency

3D technology’s impact extends beyond waste reduction; it plays a crucial role in optimizing production efficiency for tailors and manufacturers alike.

2.1 Enhanced Collaboration Among Stakeholders

The digital nature of 3D models fosters better collaboration between designers, tailors, and clients. With detailed visual representations of designs, clients can provide instant feedback. This quick exchange allows for faster iterations and modifications and ensures that the final garment aligns with client expectations. Ultimately, this collaboration reduces the risk of producing garments that are misaligned with customer desires, thereby minimizing further waste.

In the context of premium suit bespoke tailors, this means an increase in customer satisfaction and loyalty. Moreover, during the production phase, manufacturers can easily share 3D models with workshops and suppliers, ensuring that everyone involved in the process has access to the same detailed information. This accessibility streamlines communication and helps to mitigate any misinterpretations that could lead to errors.

2.2 AI and Algorithm Integration

The integration of artificial intelligence (AI) with 3D technology further enhances the tailoring process. AI-driven systems can analyze body shapes, sizes, and movement patterns to provide personalized recommendations that optimize fit. For instance, as customers engage with buying tailored suits, an AI algorithm could suggest styles or patterns that are most likely to complement their body type and preferences.

Additionally, AI can predict fashion trends based on historical data and consumer interactions, allowing tailors to create more relevant and desirable designs. This predictive capability helps producers allocate resources effectively, ensuring that fewer unsold garments end up as waste. As a result, tailors can move towards a more demand-driven production model that aligns with sustainable practices.

2.3 Cost-Effective Solutions

Utilizing 3D technology can also lead to significant cost savings for both customers and tailors. By reducing fabric waste and streamlining the production process, manufacturers can lower the bespoke suit cost. These savings can be passed down to the consumer, making bespoke suits online more accessible to a wider audience without sacrificing quality. This democratization of luxury tailoring encourages a responsible consumption approach among modern consumers.

Customers seeking inexpensive tailored suits may find that 3D technology allows brands to offer high-quality tailoring at a more competitive price point. As efficiency increases and production costs decrease, more individuals can experience the benefits of tailored clothing without straining their budgets.

3. The Future of Sustainable Tailoring with 3D Technology

As the world continues to focus on sustainability, the tailoring industry will undoubtedly see further integration of 3D technologies. Tailors that embrace these innovations will be better positioned to meet the demands of eco-conscious consumers and reduce their environmental footprints.

3.1 Continuous Advancement and Innovation

The ongoing advancements in 3D technology promise even more sophisticated solutions. Future developments may include AI-driven fitting algorithms that adapt to a client’s body shape over time, enhancing the accuracy of measurements with each new purchase. This means that once customers engage with buying a tailored suit, their experience becomes increasingly refined and exactly tailored to their evolving preferences.

Moreover, as technology becomes more affordable and accessible, an increasing number of tailors will adopt these practices, leading to industry-wide changes. Those who invest in 3D technology will likely stand out in a competitive market, offering superior personalization while committing to a sustainable future.

3.2 Shaping Consumer Behavior and Expectations

As awareness of environmental issues increases, consumers are actively seeking brands aligned with their values. The innovative use of 3D technology in tailoring not only addresses sustainability but also reshapes consumer perceptions and behaviors. Clients increasingly understand the environmental impact of their purchases and prefer brands that mitigate waste through advanced technologies.

This shift in consumer behavior places pressure on traditional tailoring businesses to adapt or risk obsolescence. Brands that prioritize sustainability and transparency will attract a loyal customer base, paving the way for a new era in fashion.

4. Conclusion: Enhancing Bespoke Suits Online With Support From 3D Technology

3D technology has become a pivotal force in transforming the tailoring industry, offering unparalleled accuracy in fit and enhancing production efficiency while significantly reducing material waste. These innovations enable premium suit bespoke tailors to meet the evolving needs of modern consumers, who increasingly prioritize both quality and sustainability. By embracing such advancements, tailors not only elevate their craftsmanship but also play a crucial role in promoting environmentally responsible practices within the fashion industry.

As you explore bespoke suits online, you’ll find that the integration of 3D technology not only enhances the design process but also ensures a personalized experience that caters to individual preferences. Whether you are looking for a classic formal style or a more contemporary design, 3D technology makes it easier to find the perfect fit that reflects your unique style without compromising your values.

For those interested in exploring tailored options, check out our extensive collection of men’s suits and women’s suits that showcase the beauty of bespoke tailoring enhanced by modern technology. Each piece is thoughtfully crafted to ensure you look and feel your best.

For more information on sustainable tailoring and guidance on selecting the perfect suit, visit Rosie Hong’s homepage. Step into a world where technology meets tradition in tailoring—your perfect fit awaits!